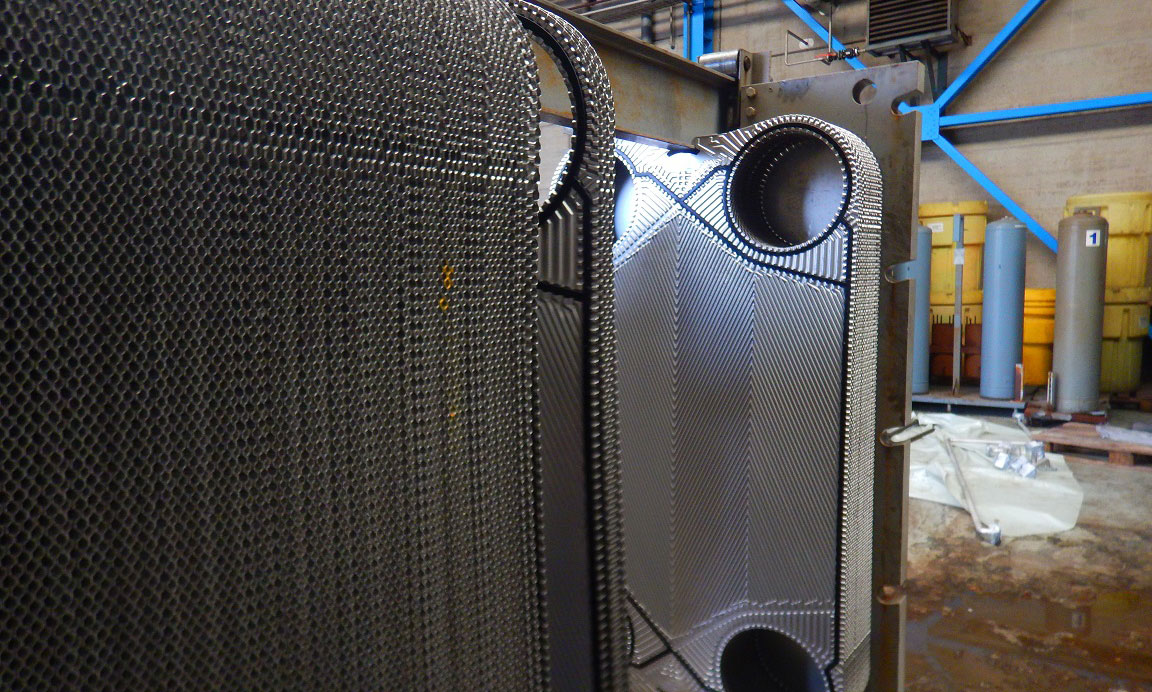

Reconditioning of plate heat exchangers

We treat plate heat exchangers in our workshop and on site

Treatment in our workshop

If the client desires we open the plate heat exchangers on site, dismantle the apparatus and transport the plates to our workshop.

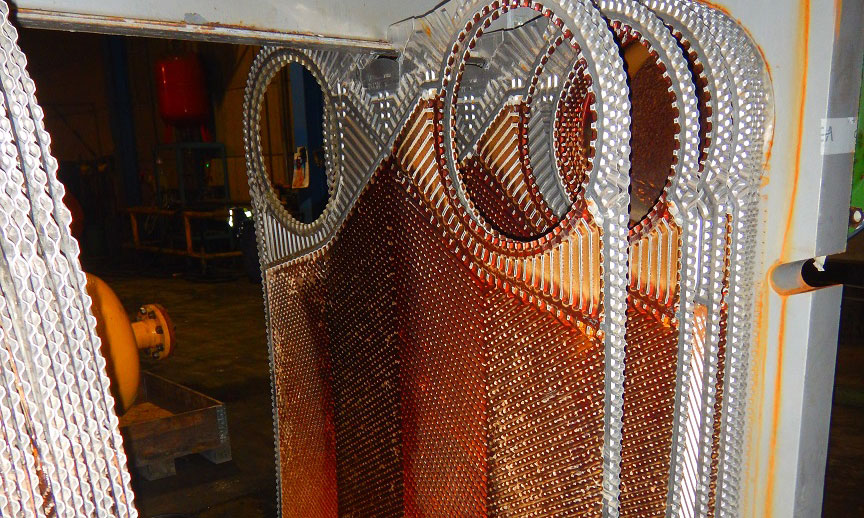

After visual inspection, the plates are cleaned.

The applied procedure depends on the kind of pollution:

- low pressure warm water cleaning

- degreasing

- decarbonisation

- lime removal

- chemical cleaning

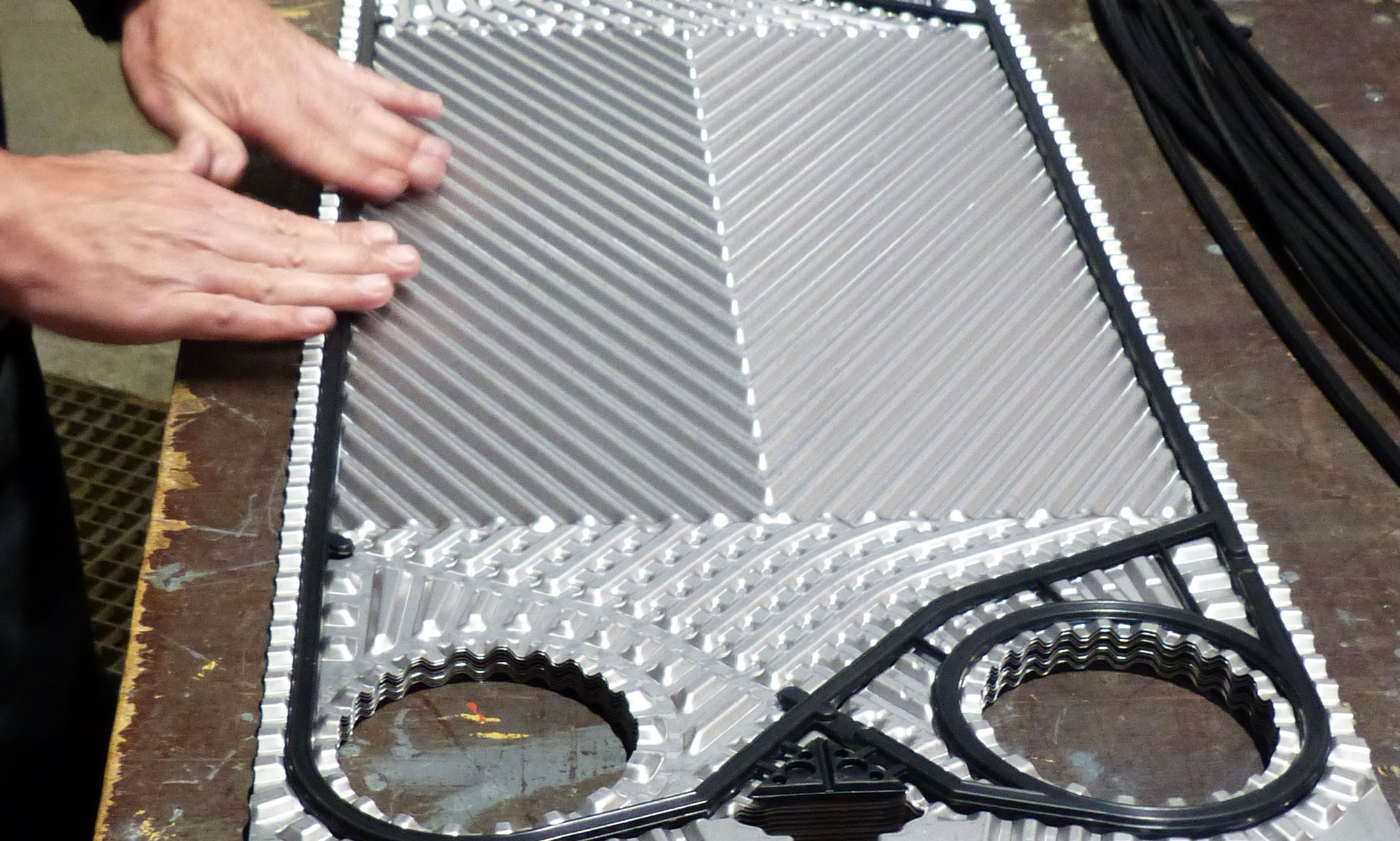

Next, the old gaskets are removed.

On request the heat exchanger plates are checked on hairline cracks with penetrating liquid.

After that, the gasket grooves are checked and cleaned

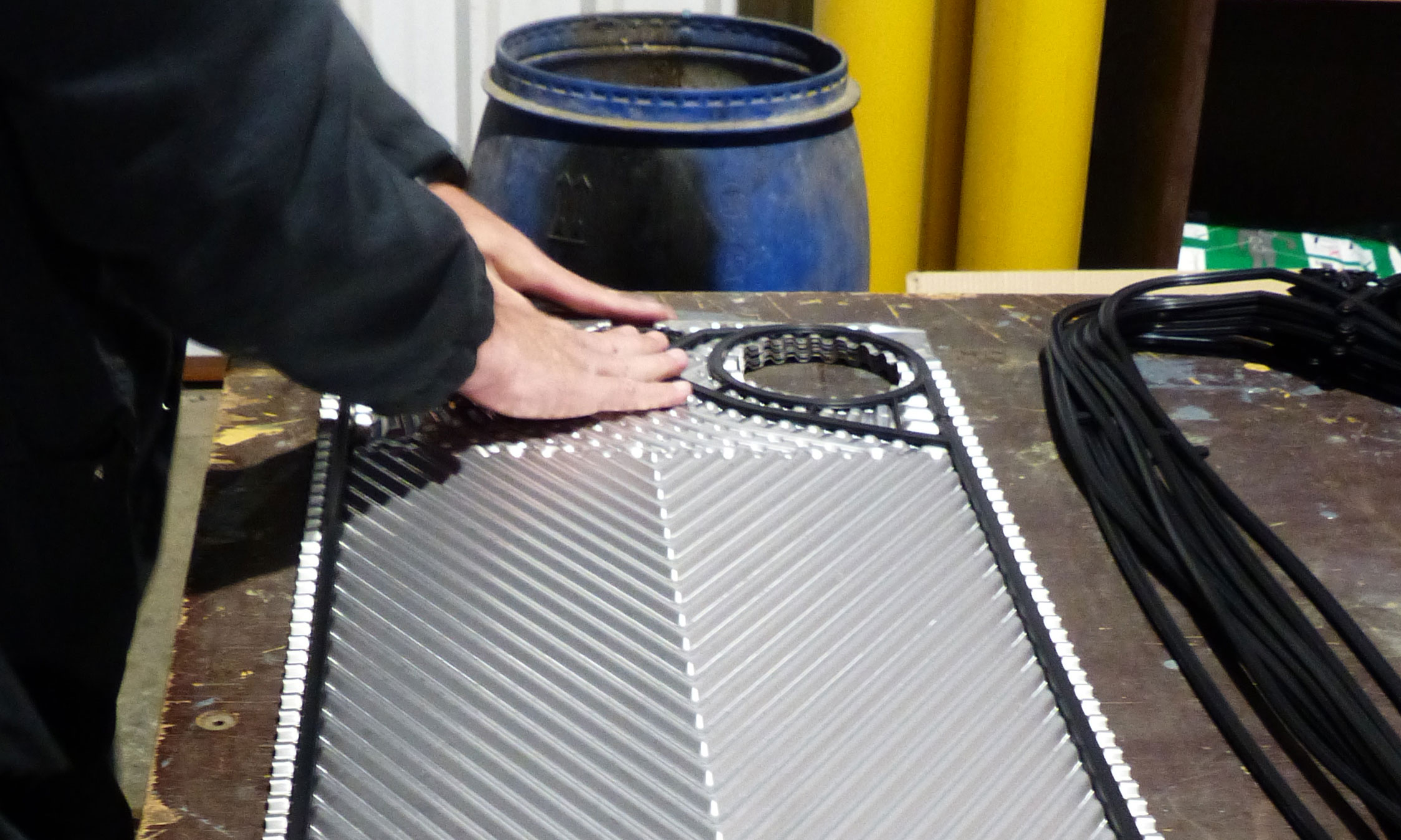

The new gaskets, in the quality adapted to the required application are placed on the plates.

At the request of the client we can also do:

- final inspection

- transport to the client

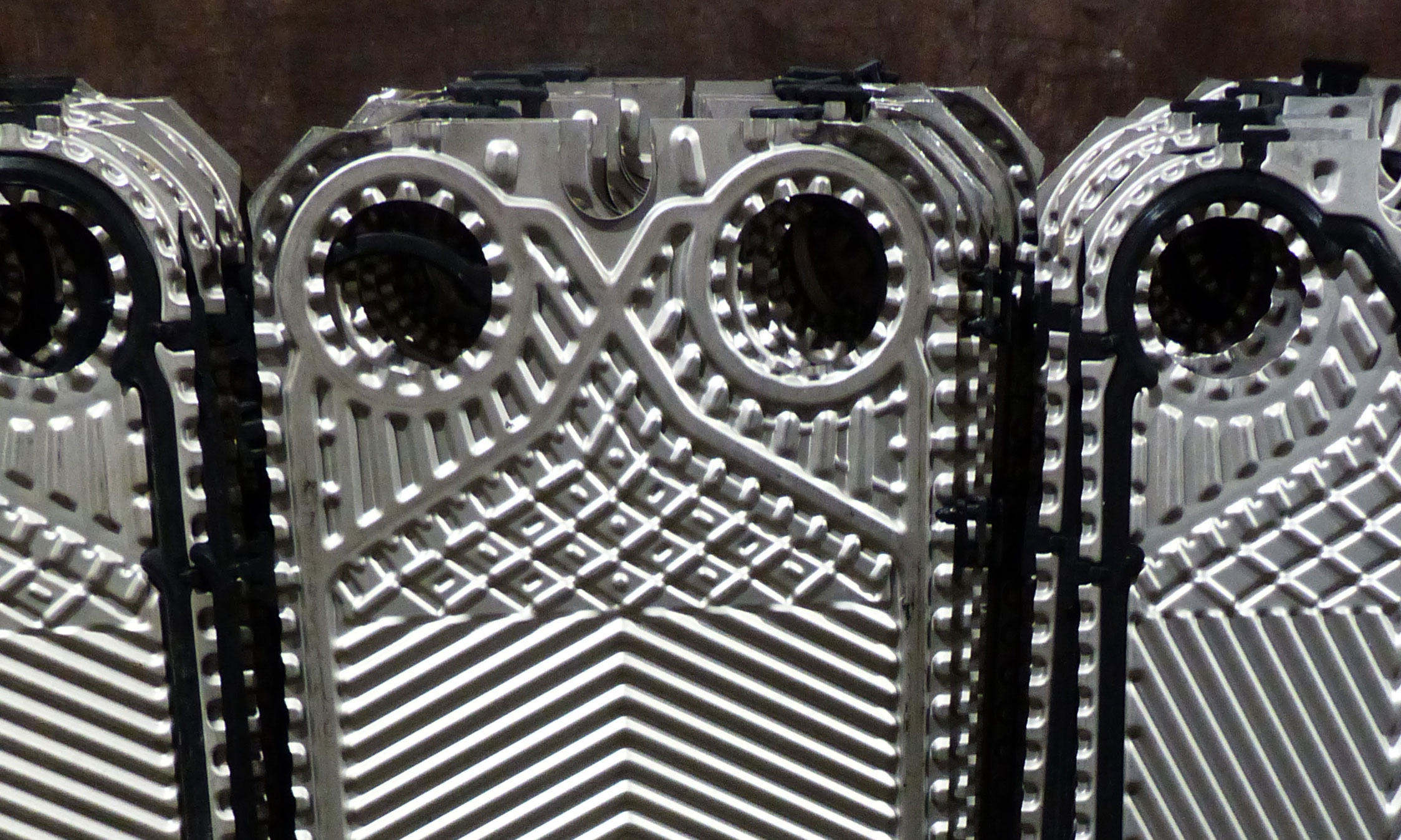

- mounting the heat exchanger plates

- closing the heat exchanger

- performing a pressure test

Treatment on-site

If there is not enough time to open the heat exchanger, we perform a chemical cleaning on site. In this case, one of our circulation units is connected with the liquid side(s) of the apparatus.

On site, we perform following treatments:

- degreasing

- decarbonisation

- lime removal

- removal of chemical pollution

Not taking into account the above mentioned works, ROMARCO supplies new gaskets in various qualities and measures.

Contact us